Get Started in the Metal Roofing Business

3 Machines for One Low Price!!

Buy This Package and get 3 Extra Un-Coiler Mandrels FREE

($3000.00 value)

The Package Includes:

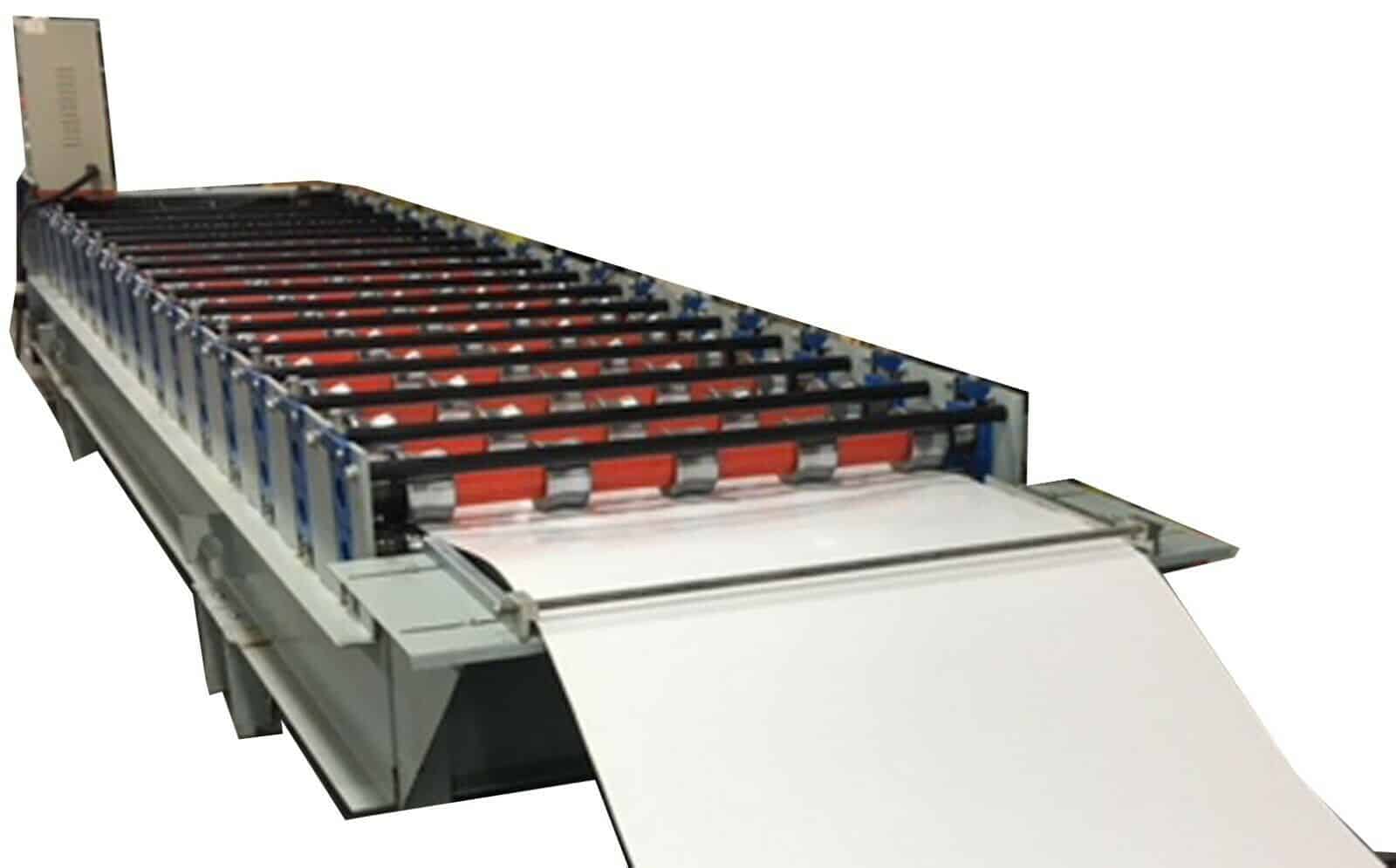

TUFF – RIB / AG PANEL ROLL FORMING MACHINE

NEW 16 Station AG Panel – Classic Rib – Tuff Rib Roll Former

- 36″ panel , ribs on 9″ centers, coil width 40 7/8″ – 41″

- (36″ width is with 50ksi material, higher 80ksi will produce a slightly wider panel and lower 30ksi will produce a slightly narrower panel)

- Tooling design forms all ribs at the same time. This reduces “oil canning”

- Tool steel roll dies, hardened, and chrome plated.

- UP-CUT-SHEAR – DOUBLE CYLINDER

- The up cut shear makes stacking of formed panels much easier. The micro burr on the end of the formed sheet is turned up by the up cut shear, so it will not scratch the sheets in the stack. The end of the newly formed sheet can slide on the top of the sheet stack, it does not need to be kept off of the stack to avoid scratching as with a down cut shear.

- 16 Batch Multi-Speed Controller – Enter up to 16 lengths and quantities

- Wireless Remote Jog Controller – allows one person to feed coil into the machine

- Includes 8,500 lb manual un-coiler

- Designed, Final assembly, and Testing in USA

- Power is 220v 3 phase 60hz, single phase converters are available

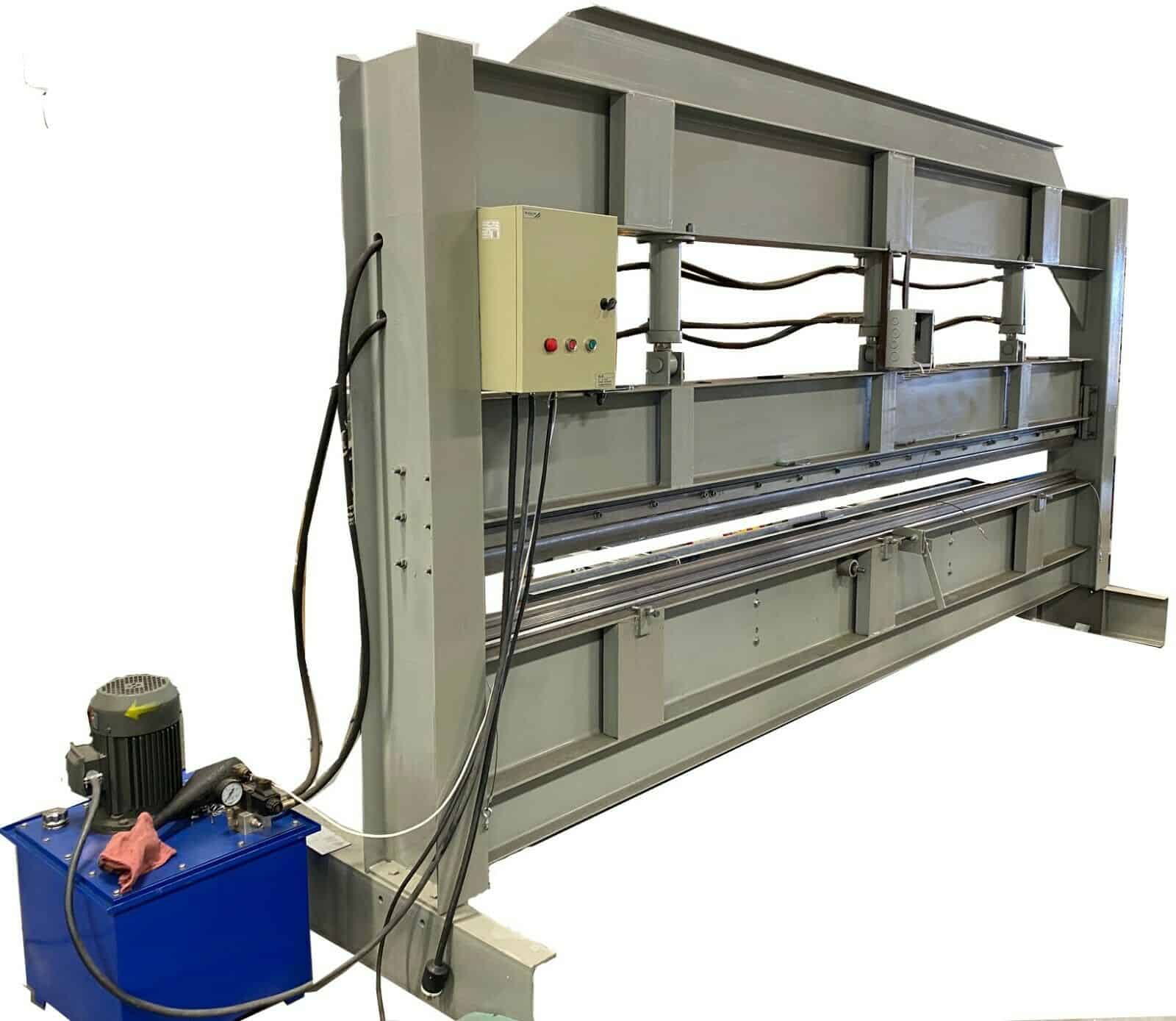

TRIM or FLASHING PRODUCTION SYSTEM (2 Machines)

- 14′ Hydraulic Sliding Die Press Brake – with Power Back-Gauge and digital position readout – 220v single phase (will hem trim)

- 4-Cut Slitter with Manual cut-off and 8,500 lb un-coiler – 120v single phase

Loaded on your Truck in Sunnyside Wa.

$68,900.00

Video – See operation of this Trim Production System: